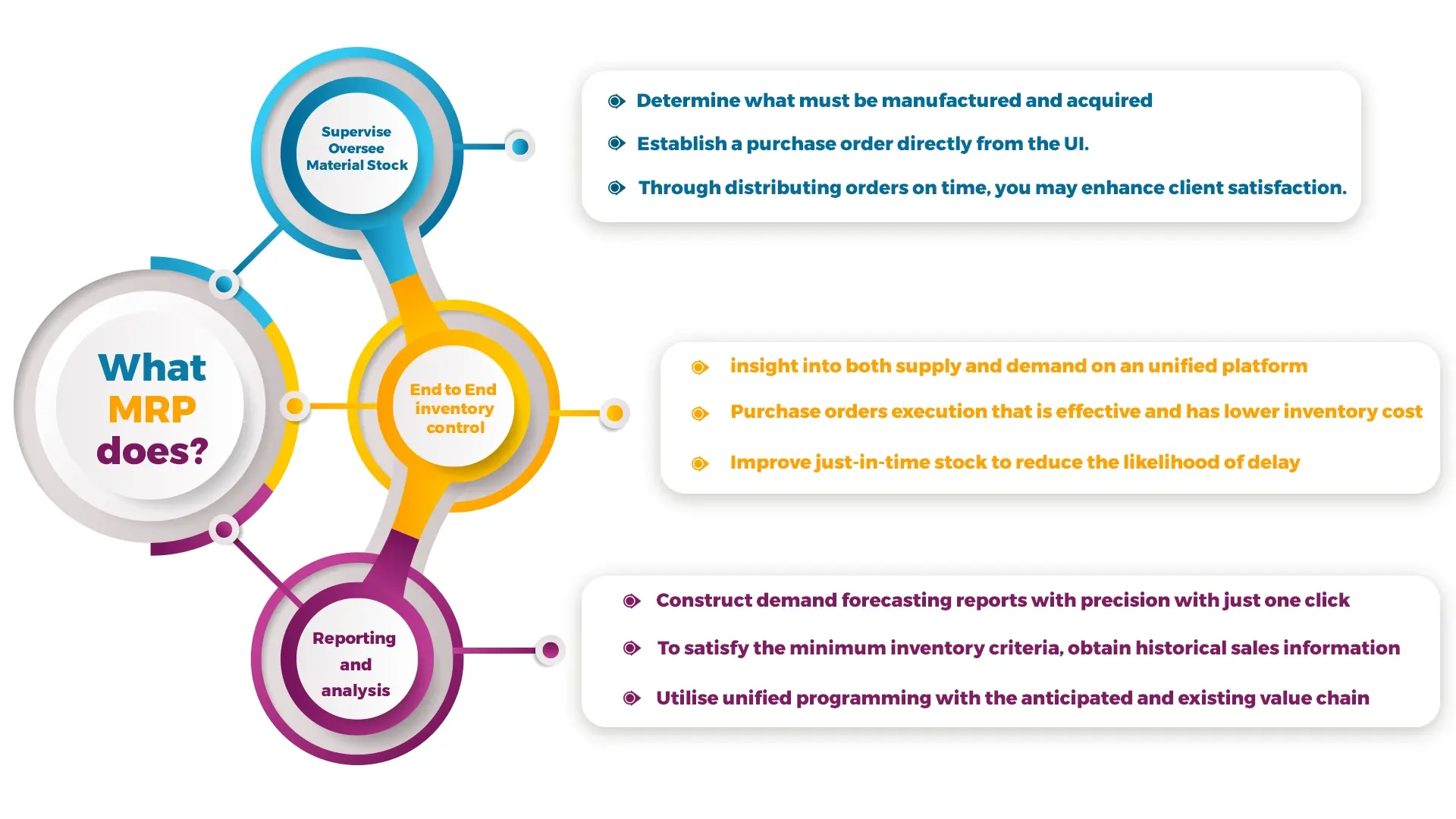

Factovize MRP gives firm visibility into the inventory requirements needed to fulfill the demands. This in turn enhances your company’s inventory levels and production schedules. Also it enables companies to increase supply. No need to manually estimate what is indispensable to accomplish company obligations over the course of many hours.

Utilize customer orders, minimum inventory requirements, or repeat periodic orders to forecast inventory consumption.

Obtain precise inventory levels to ensure you have quite enough production raw materials whenever you require them.

Estimate and retain minimal inventory levels to deliver & distribute the manufactured product promptly.

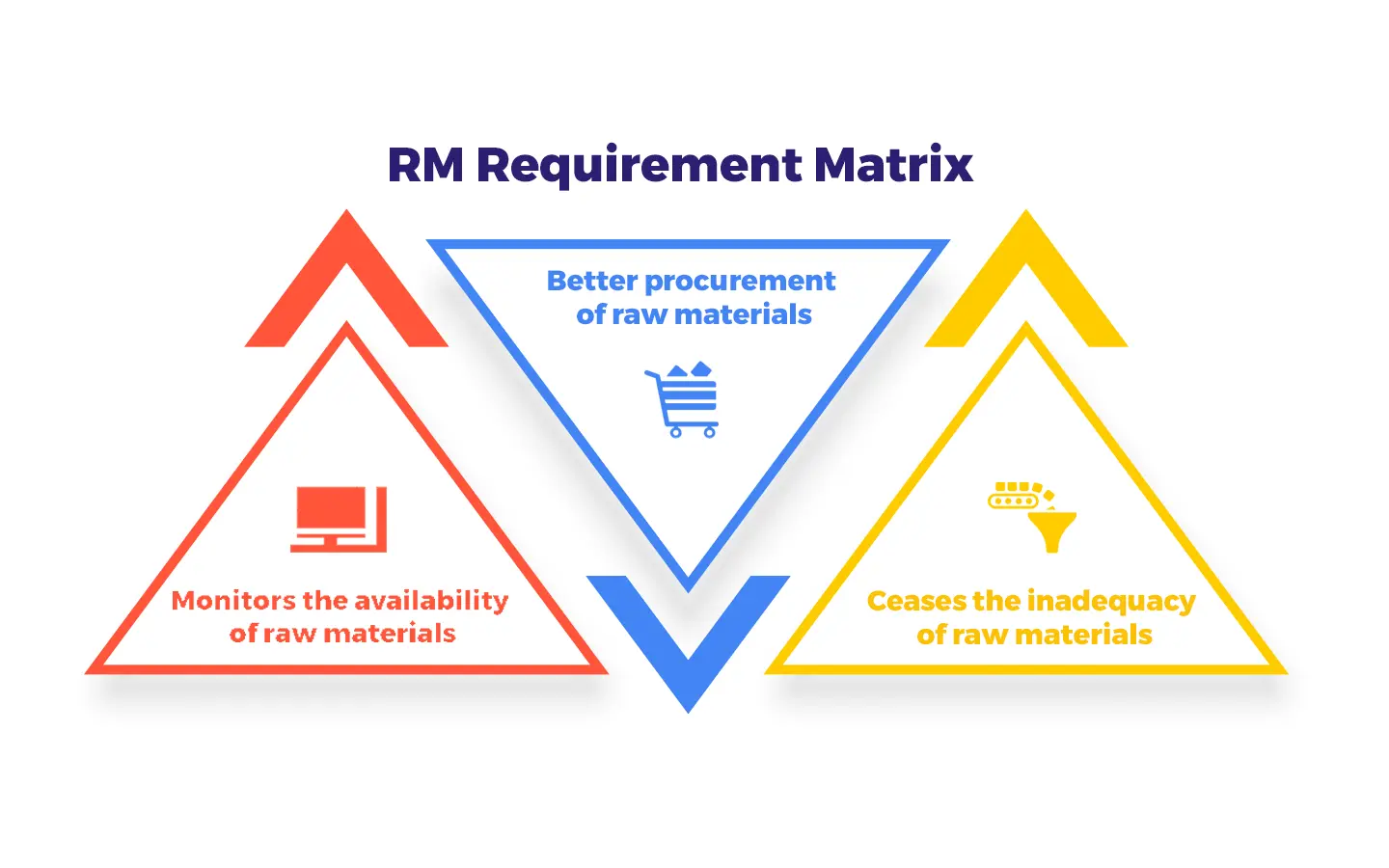

Certain things are crucial for optimizing workflow. They’re: determining what raw materials & accessories are accessible, what else to obtain & when to acquire them. A clever system is necessary for raw materials & accessories planning to track the manufacturing process. This helps to discover potential purchases that are necessary. It enables us to compare those purchases to the production plan & anticipated material deliveries. Procurement managers set-up MRPs to automatically contact vendors when a purchase is essential.

It is critical to possess a realistic idea of inventory throughout the organisation. It aids in understanding what items are on hand and which are on their way or have purchase orders issued. Due to insufficient availability of raw materials, manufacturing of products gets ceased. Tracking of place order process helps to prevent this type of ceasing.

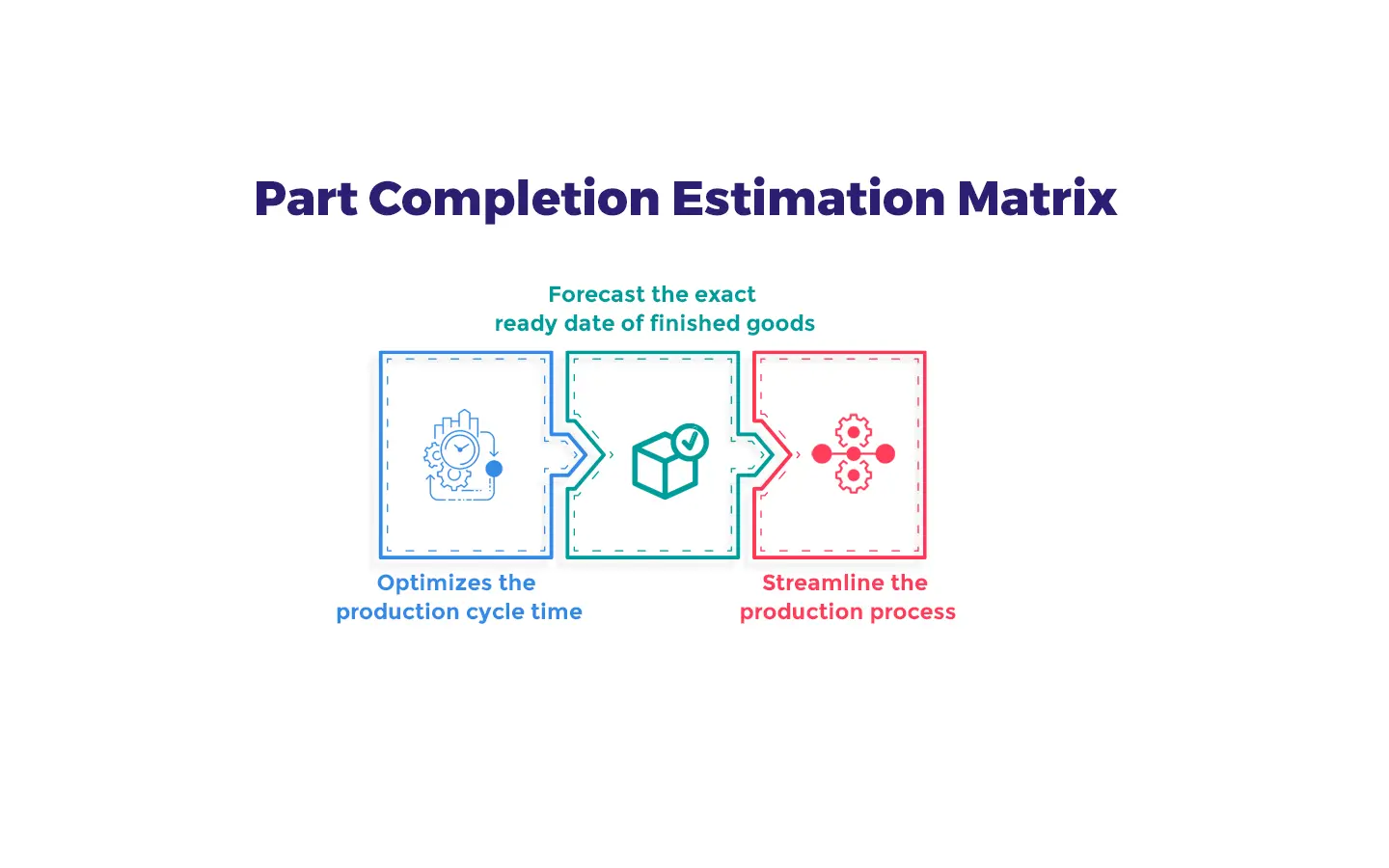

It is essential to maintain a holistic idea about the status of inventory . It includes : where that inventory is, and when it will arrive in your industry. Therefore, it helps to predict the approximate time by when the work will be completed.

Raw material plays a crucial role in the whole process. Due to the inadequacy of raw materials, the manufacturing process gets ceased. Preventing this is very significant. Regular monitoring of the availability of raw materials helps prevent ceased manufacturing process. Knowing the amount of raw materials required for the process prevents production from ceasing.

Our MRP software is also utilized to estimate the time when will the part be ready for undergoing the next process. This helps the manufacturers to determine the time by when the whole product will be ready.

Kickstart manufacturing growth!

Explore our Smart Factory solutions tailored to meet your requirements